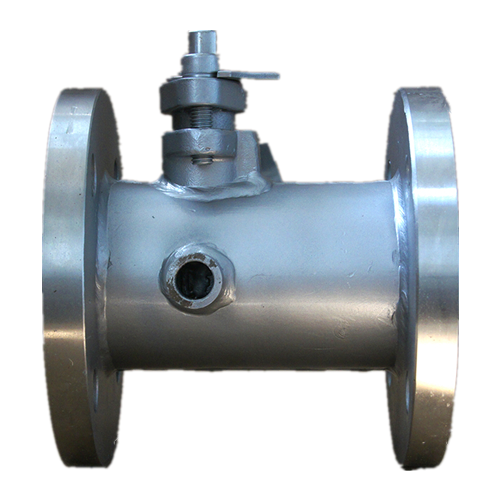

BQ41F insulated jacket ball valve has good thermal insulation and cold characteristics, and the valve diameter is consistent with the pipe diameter, but also can effectively reduce the heat loss in the pipeline medium. According to the different structure of ball valve, there are integral insulation ball valve, two-piece insulation ball valve, sandwich insulation ball valve and other structural forms, widely used in chemical, petroleum, pharmaceutical, metallurgy and other industries in the system pipeline.

Advantages:

1. The fluid resistance is small and its resistance coefficient is equal to that of a pipe section of the same length.

2. Simple structure, small size, light weight.

3. Tight and reliable, the sealing surface material of ball valve is widely used in plastic, good sealing, and has been widely used in vacuum system.

4. Easy to operate, open and close quickly, from fully open to fully closed as long as the rotation of 90°, convenient for remote control.

5. Convenient maintenance, ball valve structure is simple, sealing ring is generally active, disassembly and replacement are more convenient.

6. When fully open or fully closed, the sealing surface of the ball and seat is isolated from the medium. When the medium passes, it will not cause the erosion of the sealing surface of the valve.

7. A wide range of applications, from small diameter to a few millimeters, to a few meters, from high vacuum to high pressure applications.