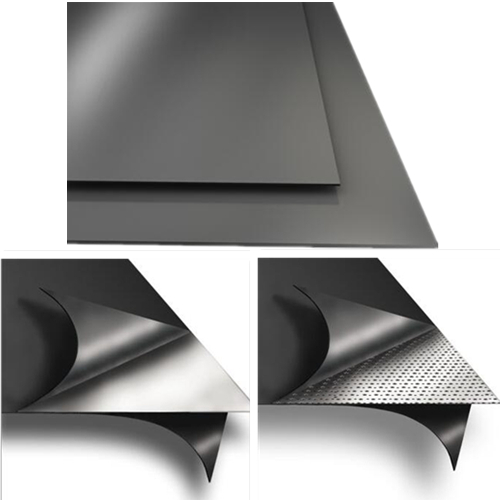

Graphite Foil is an excellent sealing material for high temperature, high pressure transfer of liquids, gasses, steam, chemicals, and corrosives. The material is manufactured from high purity, high crystalline natural graphite flakes, which are processed into continuous foil by special acid and thermal treatments to produce expanded graphite crystals. The expanded graphite crystals are then formed into foil through a calendaring process without any resins and binders.